Proper lighting plays a pivotal role in warehouses and factories, directly impacting safety, productivity, and costs. Poor lighting contributes to approximately 15% of workplace injuries, while adequate illumination can reduce accidents by up to 25%. With lighting accounting for 30-40% of energy use in commercial buildings, industrial LED lights offer a solution that cuts energy consumption by as much as 70%. Selecting high-brightness garage lights for factories ensures compliance with safety regulations and minimizes potential OSHA fines, which can exceed $13,000 per violation. Key factors like brightness, energy efficiency, durability, ease of installation, and cost must guide the decision when choosing waterproof LED garage lighting systems or workshop lighting solutions.

Key Takeaways

- Good lighting in warehouses and factories can lower injuries by 25%. Pick bright lights to improve safety and work output.

- LED lights use 70% less energy than old systems. This saves money. Use smart controls like motion sensors for better efficiency.

- Choose strong LED lights that last over 50,000 hours. They cut maintenance costs and work well in tough conditions.

Key Criteria for Choosing Garage Lights

Brightness and Coverage

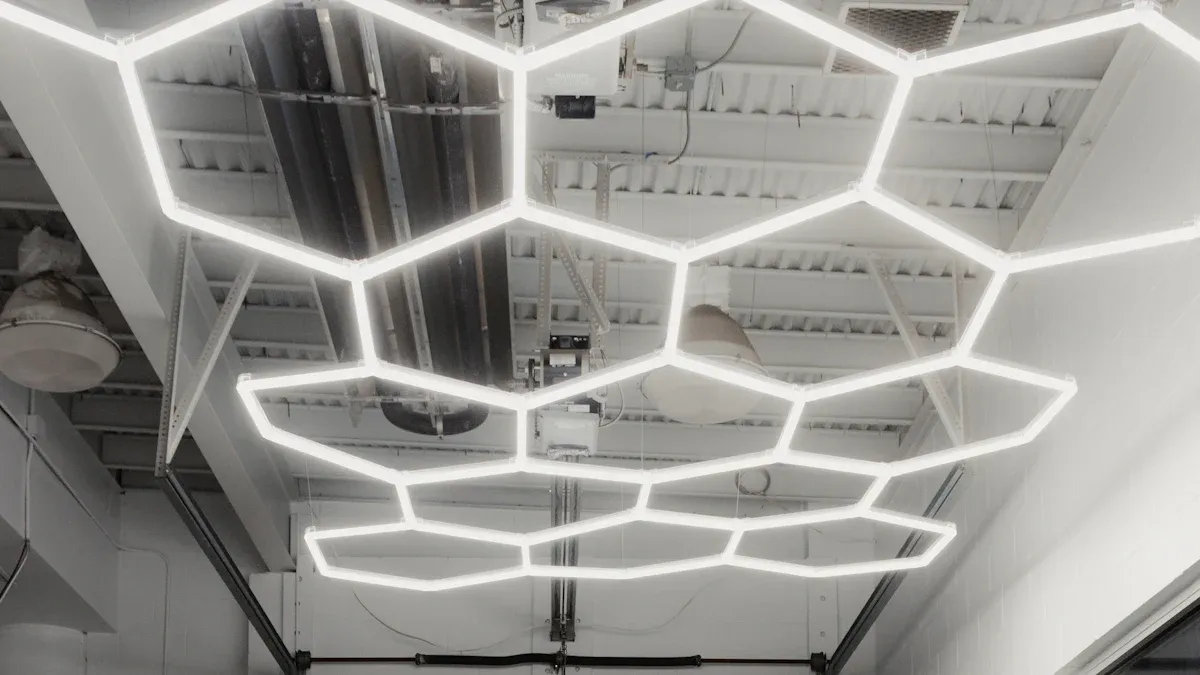

Brightness and coverage are critical factors when selecting garage lights for industrial spaces. Proper illumination ensures safety and productivity. For effective lighting, aim for fixtures that provide between 4,000 and 10,000 lumens, depending on the size of the area. LED lights excel in this regard, offering superior brightness while consuming less energy. Additionally, the ideal color temperature for garages ranges from 4,000K to 6,500K, ensuring optimal visibility and comfort.

Post time: May-03-2025